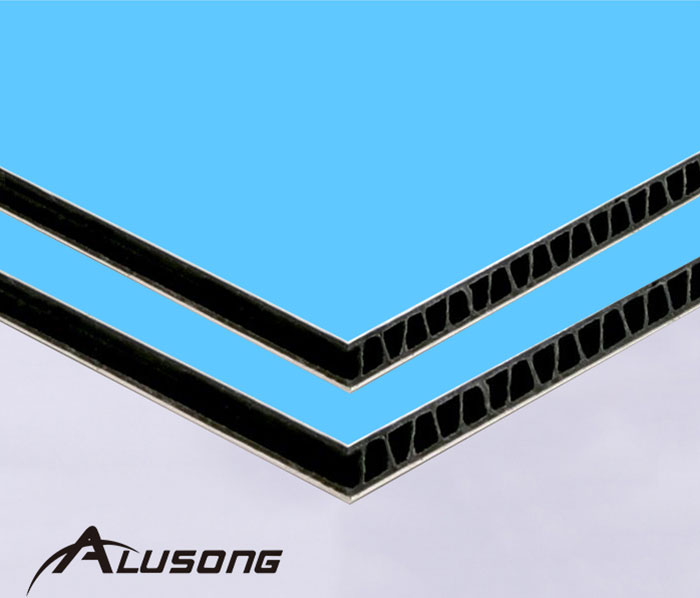

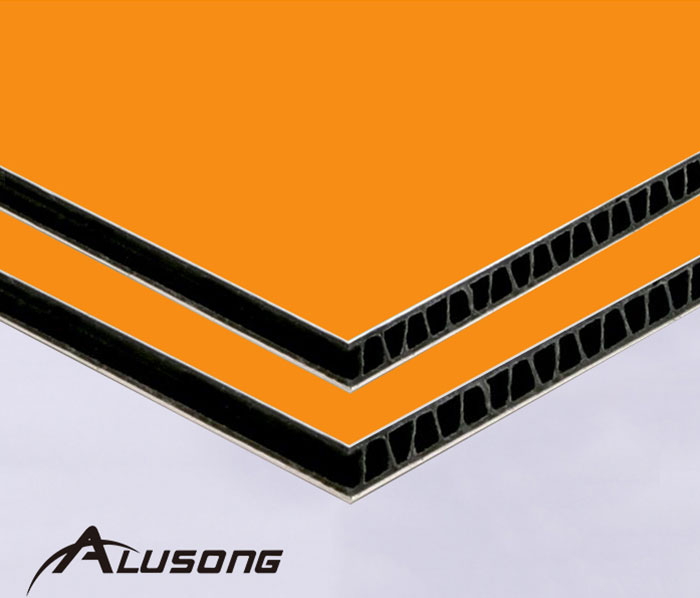

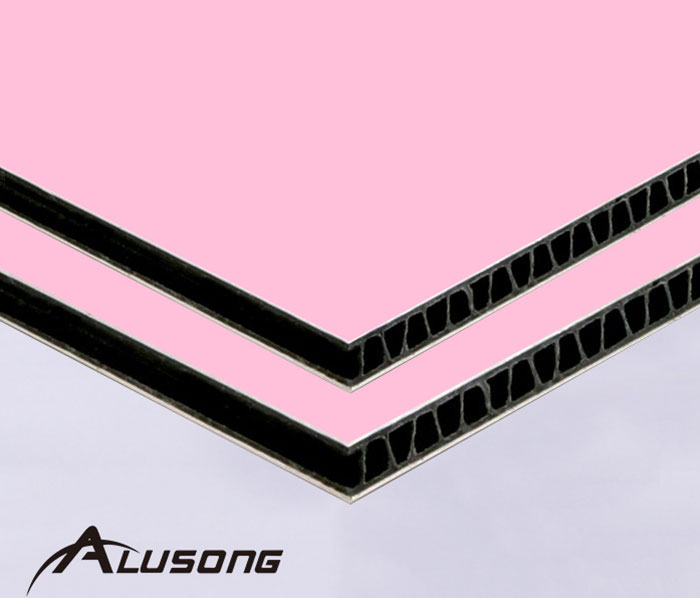

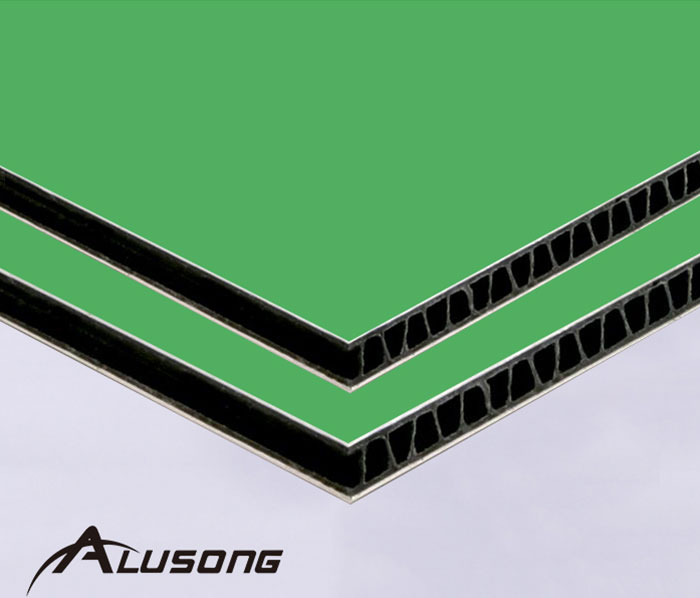

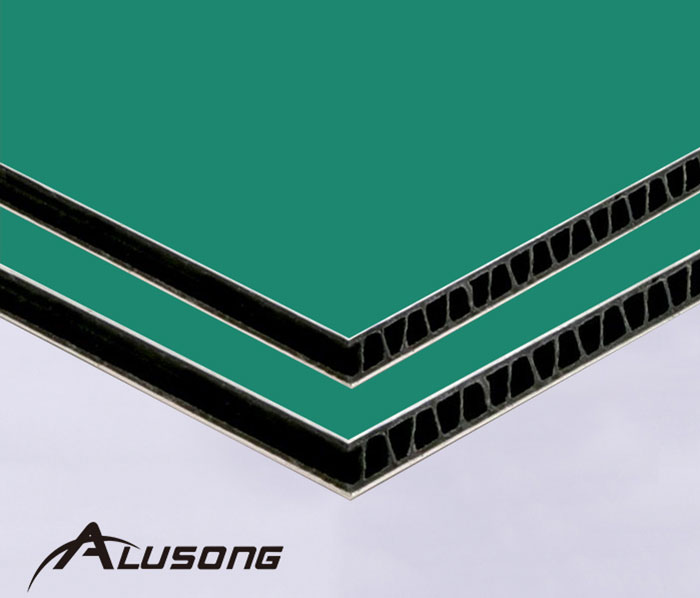

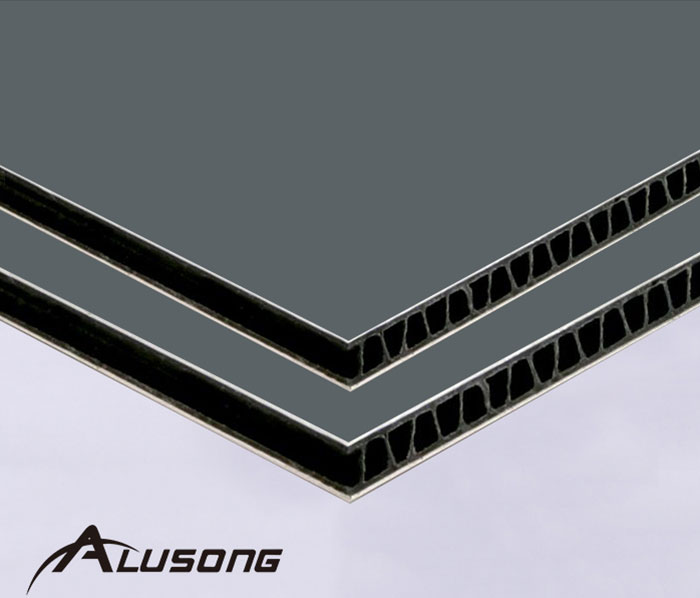

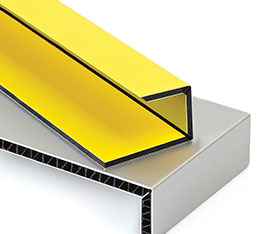

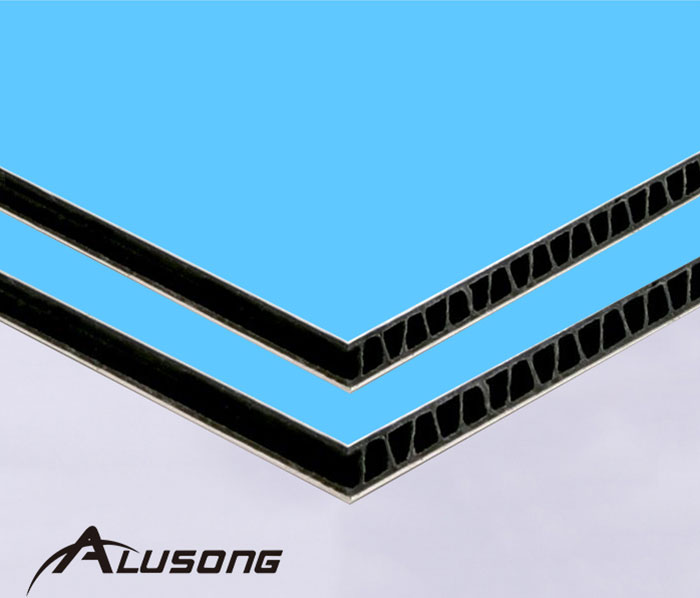

Made using the highest grade materials, ALUSONG- Digital offers superb rigidity and impact resistance together with a smooth, flat surface. The superior Polyethylene core, specially developed paint system and unique easy-peel protective film combine with a 0.20mm alloy skin to provide a panel of outstanding quality. ALUSONG- Digital printing aluminum composite panel comes with an optimized lacquer system for direct-to-substrate digital printing showing excellent ink adhesion which allows advanced printing speed. The higher performance means higher output and lower costs.

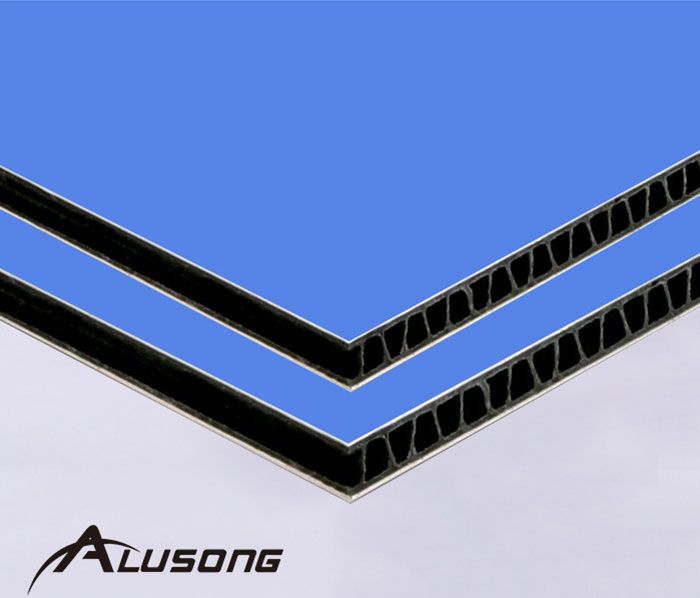

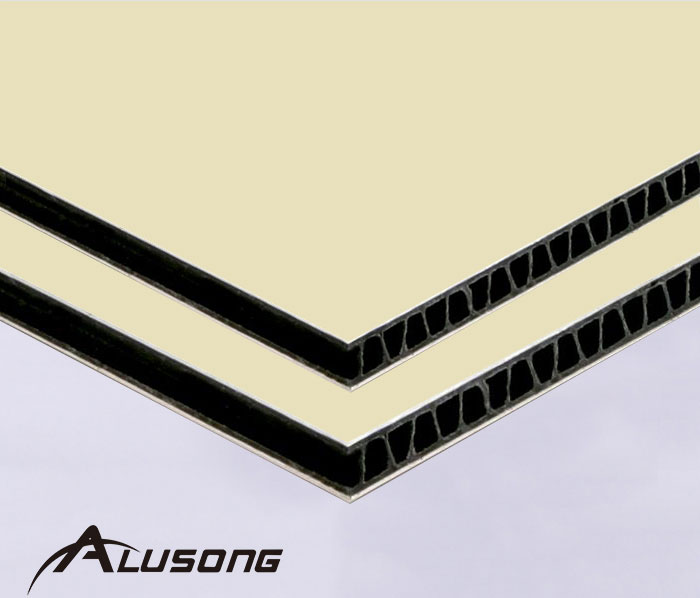

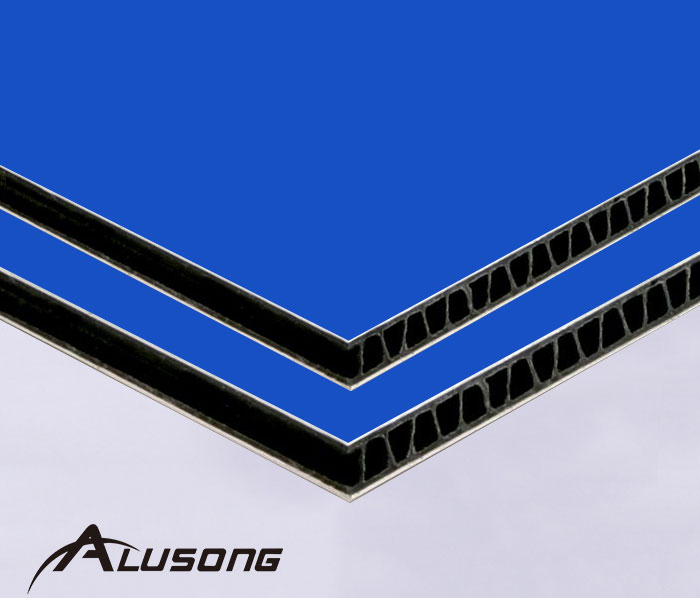

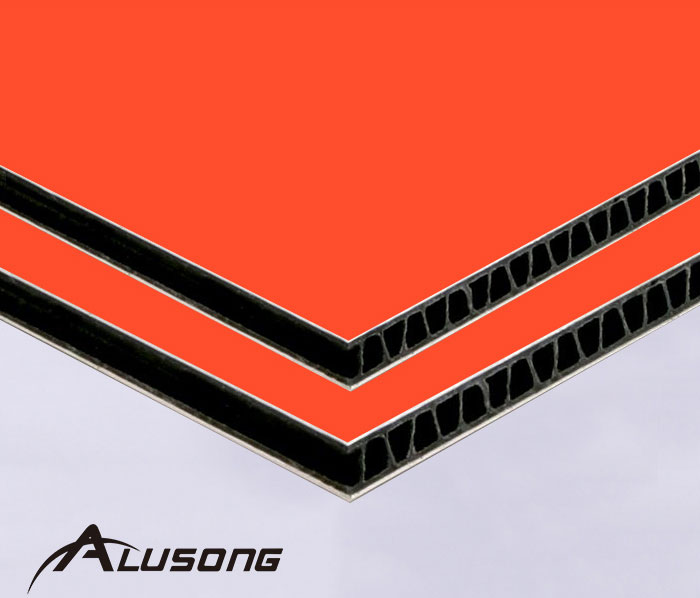

Available in matte/matte or gloss/matte, both sides of the panel have a finish that has been developed specifically for digital and screen printing. This helps display colors with increased brightness and intensity with the added benefit of greater durability. The high quality film provides excellent protection and is designed to remove smoothly and easily, leaving no residue on the panel. Digital printing aluminum composite panels are especially useful for digital UV flat printing, which has the outstanding features of smooth glossy surface, high definition printing and good printing ink absorption.

| Surface coating | High performance polyester coating |

| Aluminum alloy | AA1100 series, AA3003 series |

| Aluminum skin | 0.10mm,0.12mm,0.15mm,0.18mm, 0.21mm,0.25mm,0.30mm |

| Panel thickness | 2mm, 3mm, 4mm |

| PE core material | Non-toxic low density polyethylene |

| Panel width | 1000mm 1220mm 1250mm 1500mm |

| Panel length | 2440mm,3050mm4050mm |

| Backing coating | PE coating or primer coating |

| Glossy | 20%-80% |

Dimensional tolerance:

Panel width: ±2mm Panel length:±3mm

Panel thickness: ±0.2mm Panel diagonal: ≤5mm

Aluminum sheet thickness: ±0.01mm

Good flatness and fineness

Strong ink absorption.

Easy peeling of protective film

High resistance to peeling

Superior weather resistance

Light weight and easy to process

Excellent fire resistance properties

Coating evenness

Diversified colors

Easy for maintenance

Impact resistance

· Sign Making, Way finding

· Direct UV & Screen Printing

· Standoff Lettering

· Lightweight Hanging Signs

· Displays &Vinyl Application

· Modular Sign Systems

· Hoarding Panels

· Exhibition Design

· Outdoor Advertising

-

Application

-

Application

-

Application

-

Application

| Description | Test standard | Polyester |

| Thickness of coating | Polyester paint ≥16um | 16um to 18um |

| Coating flexibility (T-bend) | Polyester paint≥3T | 3T |

| Color different | △E ≤ 2.0(follow color sample) | ΔE ≤ 2.0 |

| Pencil hardness | ≥HB | ≥2H |

| Chemical resistance | 2%HCI or 2% NaOH test in 24 hours -No change | No change |

| Coating adhesion | ≥ 1grade for 10810mm2gridding test | 1grade |

| Resist solvent | 100times with Dimethylebnzene without change | No change |

| Boiling water resistance | 2 hours without change | No change |

| Peeling strength/stripping strength | Average ≥5N/mm of 180oc peel off for panel with 0.21mm alu.skin | 5N/mm |

| Impact test for paint | 20KG.cm impact-paint no split for panel | No split |

| Abrasion resistance (L/Mil) | NIL | NIL |

| Temperature resistance | -40℃ to +80℃ temperature without change of color difference and paint peel off, peeling strength average drop rate≤10% | Change of glossy only, no paint Peel off |

| Coefficient of linear Thermal Expansion | 100℃ temperature difference | 2.4mm/n |

| Detergent resistance (3%) | ASTM D2248 | No change |

| Humidity Resistance (3000hrs,100%RH,100°F) | ASTM D2247 | No change |

| Salt spray resistance (3000hrs,5% salt) | ASTM B117 | No change |

| Resistance to Staining | 600h radiate in 800W/M2 in humidity condition, glossiness deviation less grade 2, color difference ≤4.0 | No change |